Solutions

Enterprise solutions

Industries

Why Supplyframe

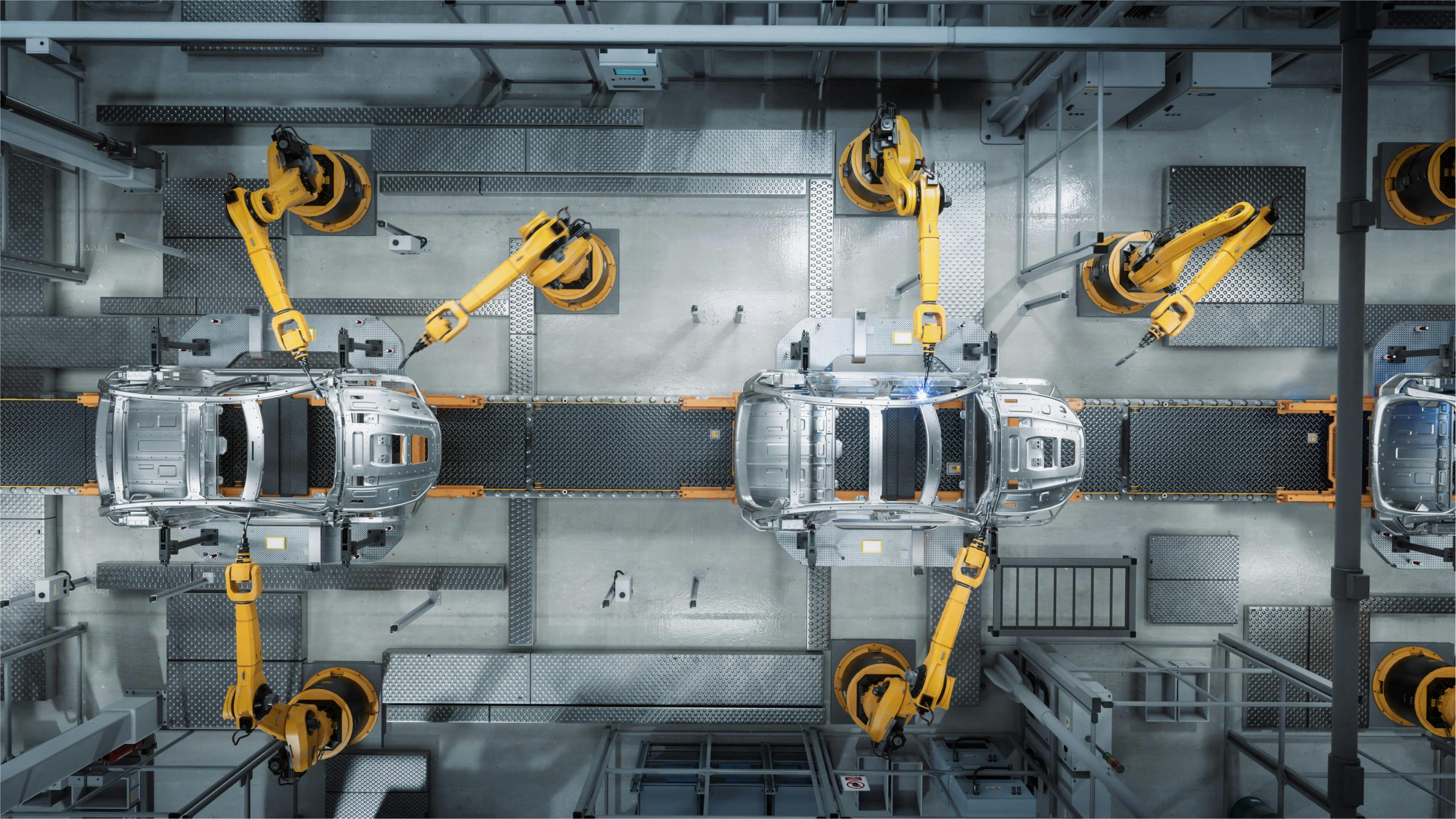

Transportation and Automotive

Proactively navigate supply chain disruptions and monitor component availability while accelerating toward innovation and sustainability goals.

Don’t let Disruption Catch You Off-Guard

Validate and De-Risk Your BOM

Supplyframe’s real-time intelligence and Risk Index cover over 650 million components, allowing your teams to validate an entire product BOM and choose alternates in minutes.

Design With Sustainability in Mind

Understand each component’s carbon impact with emissions data that ensures your teams are improving the accuracy and visibility of each BOM throughout the design-to-source process.

Illuminate Blind Spots in Your Supply Chain

View forecasted supply, demand, pricing, and lead time metrics across over 275 electronics commodities to stay ahead of market dynamics across multiple tiers of your suppliers.

Solutions for Automakers and Suppliers

NPI

Transform new product introduction with capabilities that allow teams to “shift left” and address risk at the point of design.

Learn More About NPIDirectSource

Commodity IQ

Find out What’s Next for Automotive

Download the case study to see how Design-to-Source Intelligence prepares automotive suppliers like Molex for what’s next.

Loading...

Shift Left

DSI Solutions for Suppliers & Distributors

Supplyframe Media SolutionsSupplyframe DesignSenseSupplyframe CPQSupplyframe Companies

SamacsysCopyright © 2025 Supplyframe